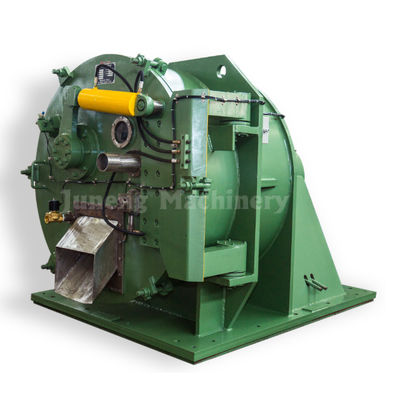

Automatic Discharge Peeler Centrifuge Starch Separator

Product Application

The Siphonic Centrifuge is a fully-automatic centrifuge capable of continuous operation and batch processing. Available in two configurations: Siphonic Scraper Centrifuge (GKH series) and standard scraper centrifuge (GK series).

The scraper centrifuge offers both automatic and manual operation modes, enabling complete cyclic processing including feeding, dehydration, washing, and discharge of materials.

Compared to standard models, the siphonic scraper centrifuge generates vacuum-like siphonic force, delivering superior production capacity and separation efficiency. Particularly effective for materials with small solids, high viscosity, slow filtration rates, or requiring thorough filter cake washing.

Technical Specifications

| Item/Type |

GKH800-N |

GKH1250-N |

GKH1600-N |

| Drum diameter (mm) |

800 |

1250 |

1600 |

| Drum length (mm) |

450 |

600 |

1000 |

| Drum volume (L) |

100 |

355 |

830 |

| Loading capacity (Kg) |

150 |

450 |

996 |

| Drum speed (r/min) |

1550 |

1200 |

950 |

| Maximum separation factor |

1070 |

1006 |

799 |

| Motor power (Kw) |

45 |

90 |

132 |

| Size (mm) |

2030×1960×1530 |

2685×2300×1900 |

4050×2745×2295 |

| Weight (Kg) |

5500 |

10500 |

16550 |

Performance Parameters

| Model |

Capacity (wet base) T/h |

Moisture % |

Solid phase loss % |

| GKH800N |

0.8-2.5 |

5-35 |

0.05 |

| GKH1250 |

3.5-6.5 |

5-35 |

0.05 |

| GKH1600 |

6.5-10 |

5-35 |

0.05 |

Key Features

The GKH series siphonic centrifuge excels in applications requiring high production output, low residual moisture content, and thorough washing. Widely used for solid-liquid separation in food processing, pharmaceuticals, chemicals, and defense industries.

Our Services

Pre-Sales Support

- Technical consultation and inquiry support

- Sample testing services

- Factory visit arrangements

After-Sales Support

- Installation training and operational guidance

- Overseas engineer support for machinery maintenance

Certifications

Packaging & Shipping

| Size |

123 (L) × 456 (W) × 789 (D) cm |

| Weight |

1.2 Tons |

| Packaging Details |

Standard wooden crate packaging. European exports include fumigation. Alternative packaging (PE film) available for tight container spaces or special customer requirements. |

Company Profile

Juneng Group

Juneng Machinery (China) Co., Ltd., established in 2006, specializes in the research, development, production, and sales of filtration and separation equipment including centrifuges, decanters, and pumps. With four strategically located factories in Nanjing and Yixing City, we maintain rigorous quality control and customer service standards.

Our product portfolio has earned CE certification, ASME U certification, and ISO 9001 accreditation. While serving domestic markets across China, we export to the USA, Germany, Korea, Japan, and other international markets. We welcome both OEM and ODM project collaborations.

Commercial Cooperation

- International technical collaboration and knowledge exchange

- Adoption of advanced management systems from global partners in USA, Canada, Germany, and Russia

Related Products

Frequently Asked Questions

Q: How can we visit your factory?

A: International visitors can fly to Shanghai airport for pickup. Domestic visitors can arrive at Wuxi station for transportation arrangements.

Q: How do you ensure product quality?

A: Our 30+ years of manufacturing experience combines precision machining, licensed operators, international component standards, and comprehensive testing throughout production.

Q: What payment methods do you accept?

A: We primarily accept T/T and L/C at sight, along with other standard payment options.

Q: What is your warranty policy?

A: All products carry a 12-month warranty period from commissioning date.

Q: What are your shipment terms and lead times?

A: Standard delivery is 20 days, with 30 days for customized equipment. Exact timing depends on order volume and specifications.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!